In order for the food and beverage industry to be successful, high-quality heating and cooling applications must be in use.

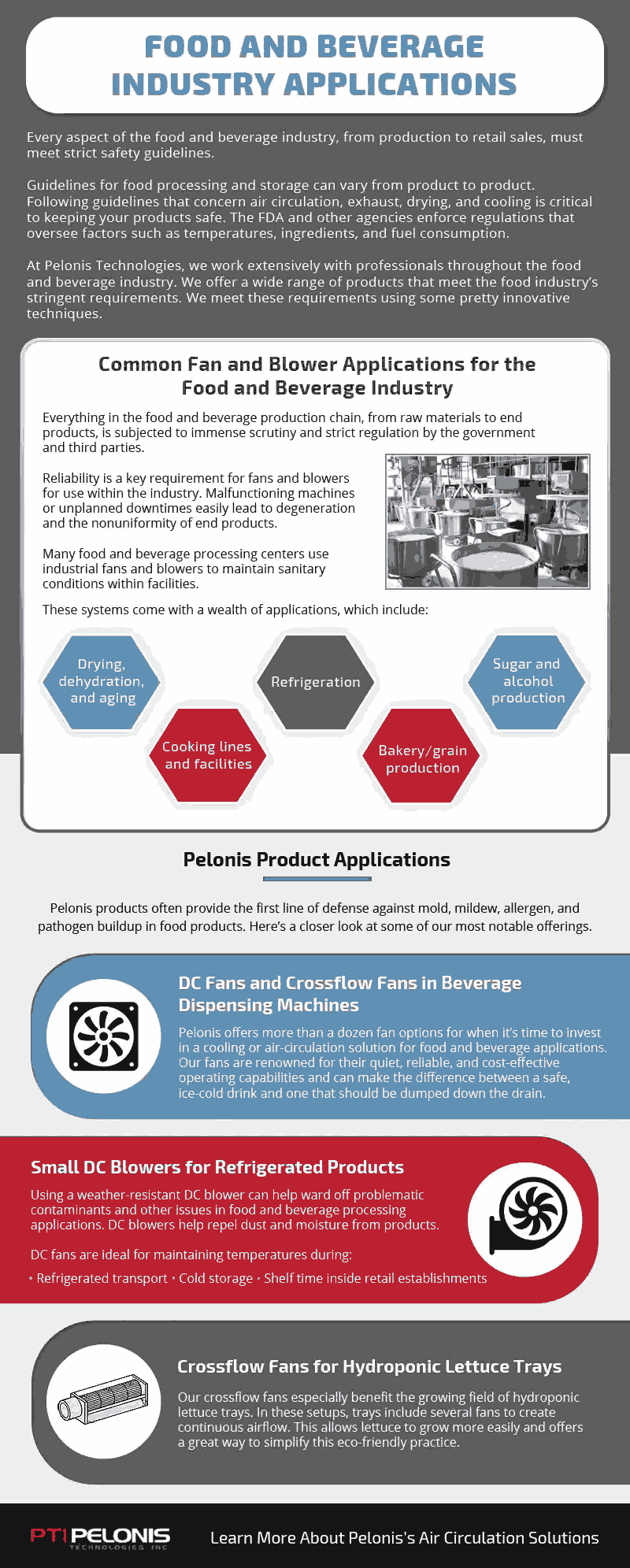

Whether your work in the industry deals with animal feed, bulk grains, meat, dairy, fruit, or vegetables, all aspects are subject to stringent safety guidelines for storage and processing. The FDA and other agencies regulate air circulation, exhaust, drying and cooling processes.

How the Food & Beverage Industry Meets Heating & Cooling Requirements

A wide variety of heating and cooling products are required in the food and beverage industry. Positive Temperature Coefficient (PTC) heaters, for example, are commonly found in coffee hot plates, food warmers, and temperature-controlled containers. Able to perform in extremely small spaces with superior heat transfer, PTC heaters offer safe, powerful and efficient operation. In fact, they produce an instantaneous flow 50% hotter than that of their coil or ceramic chip counterparts.

Small blowers offer durability and exceptional performance. AC blowers are made from reinforced plastic with an aluminum-alloy frame and feature a capacitor-run induction motor and ball bearing system. Reinforced plastic and galvanized steel constitute brushless DC motor blowers. Numerous configurations and options for both types are available, including tachometer, rotation detection, OV protection, alarm output, and thermal speed control.

DC fans offer benefits, as well. Weather resistant DC fans repel many conditions often found in food processing environments, including dust, moisture, and varying degrees of water exposure. Additionally, these fans can serve indoor cooling and ventilation applications.

Pelonis DC fans are known for their reliable, quiet and cost-effective capabilities that function well in variable environments. Another benefit is their long life span, a result of their low power consumption.

Ultra-thin flexible heaters offer superior thermal properties. Featuring lean construction and low mass, they transfer heat exceptionally efficiently. Built-in nanotechnology encourages stronger bonds, higher temperature capabilities, higher wattage and quicker heat-ups.

Producing less electromotive force than printed or wired circuit heaters, these heaters prevent cracks and breaks that could cause system failure from occurring. Finally, ultra-thin flexible heaters are easy to install and available in multiple designs to perfectly accommodate your needs.

Crossflow fans have an impressive history and reliably simple design, making them one of the most frequently used fan types on the market today. Depending on the size and design of the air flow system, a range of AC or DC crossflow fans can be employed for cost-efficient air circulation. Crossflow fans produce an even laminar, or fairly two-dimensional, airflow and are ideal for areas with limited space. Our crossflow fans are specially designed to minimize vibration and maintain a low noise ratio. In the food and beverage industry, specifically, these fans circulate air through ovens.

Certain kitchen appliance companies use crossflow fans in their refrigerators and drink dispensers. Small blowers are used for storage and processing while heater products are incorporated into plate warming products. AC fans, micro blowers, micro fans, temperature controllers, and immersion heaters are all integral within the food and beverage industry.

Farming Industry & Temperature Maintenance

Fans are essential in farming applications, especially in hydroponics — a method for growing plants that does not utilize soil and therefore requires alternative solutions to regulate temperature and other growing conditions for successful growth.

Our crossflow fans, as previously mentioned, are used to keep components in a range of industries from overheating — when used for hydroponics, they offer an ideal solution for temperature maintenance.

In fact, when one urban farming startup needed to keep their lettuce moisture trays at a certain temperature, they turned to Pelonis to provide them with the crossflow fans to help them maintain consistent temperatures. After equipping their indoor grow rooms with fans, the farmers were able to improve and maximize their lettuce growth.

To learn more about Pelonis products and how they can be utilized across a broad range of applications, download our summary catalog today.