Cooling Fan Use in Drones

|

|

|

Drone FunctionalityThe capacity to keep a UAV or drone in the air comes from the propeller, which is the heart of the device. Flight is possible using a collection of airfoils—similar to airplane wings—along with the propeller, providing lift for the aircraft. Key design elements in the propeller's blade include the angle and overall weight. The blade's angle in a rotating propeller pushes air downward while resistance to this forced air pushes the UAV upward. Essentially, the rotating propeller causes the air above it to move at greater velocity than the air below it. This is in accordance with the Bernoulli Principle, which shows that a pressure drop (which conserves energy) accompanies velocity and the low pressure lifts up the drone. However, lift cannot take place without the proper blade angle, weight, and size. |

|

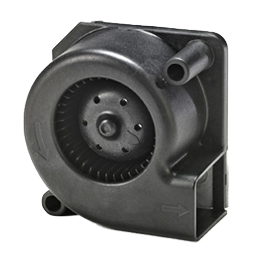

Drone CoolingThe rotation of the propeller's blade requires a motor or engine able to provide enough air velocity to produce lift. A lapse in the performance of this motor will limit or fail to provide lift, causing drone failure. The most common cause of this performance lapse is engine overheating. Such a performance failure in a military-grade drone can produce dangerous results. For example, if a UAV were to overheat and fail in hostile territory, sensitive information may be exposed and an asset costing millions of dollars may be lost. Consequently, high-performance drone designs often focus on thermal management. This is provided by cooling fans that meet the necessary size, weight, and airflow rate requirements to maintain the craft at ideal operating temperatures. In addition, proper cooling allows for greater longevity of the rotary engines used in UAVs, making cooling fans a critical element in overall cost-effective operation. |

Cooling Fans for 3D Printing

|

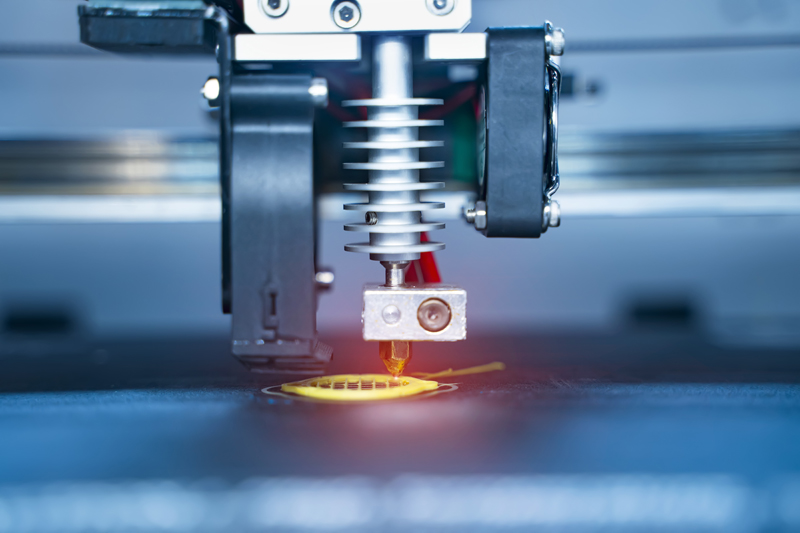

3D printers also rely heavily on cooling fans to maintain appropriate operating temperatures, which has a significant impact on the service life and cost-effective operation of what is typically an expensive piece of machinery. While 3D printers have been around since the 1980s, they have not been commonly used commercially or industrially until very recently. Their popularity among manufacturers and hobbyists alike has produced greater demand for these machines, as well as for high-performance components that help improve their operation. |

Elimination of StringingCooling fans have been used to improve bridging and overhang performance in modern 3D printers. Optimal overhang performance is crucial for maintaining the integrity of a PLA (polylactic acid) 3D-printed product. Thanks to recent innovations, cooling fans in 3D printers now have the capacity to operate at different speeds throughout the printing process. This has been integral to solving key performance problems in 3D printers, such as stringing, wherein small threads of plastic trail from the workpiece in undesirable places:

|

Improved Printing PerformanceAdditional considerations related to PLA cooling fans include:

Used properly, cooling fans produce optimal results in 3D printing by reducing stringing, promoting proper filament material flow, and creating a cleaner, more appealing final product. |

Overall Considerations of Cooling Fans

|

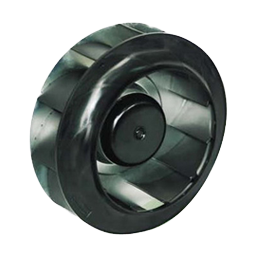

When increased size is not an option, it might be necessary to consider a different fan type. The two main considerations typically include axial and centrifugal fans, which produce varying degrees of noise. Insulation also influences fan noise, as do mounting materials meant to reduce vibration. Reducing fan noise might require the implementation of several or all of these measures to achieve the desired result An understanding of these considerations helps facilitate the optimal performance of any heating or cooling system that uses fans to move air through the device. |

Stay Cool with Pelonis Technologies

Cooling fans, exhaust fans, and blowers are essential operating components in a broad range of industrial and commercial applications. Their use helps to maintain safety, protect against damage to capital equipment or assets, and improve performance of equipment.

Each application presents unique system design challenges. Pelonis Technologies, Inc. (PTI) has the expertise required to help you find the right solution to the challenges of your operation. Our innovative system designs promote the cost-efficient operation of equipment within a broad range of applications.

For additional information about selecting a cooling fan, please download our eBook. Also feel free to contact us to learn more about our cooling fans or other services and products.

In the past decade, drone technology has made significant advancements, including the adaptation of

In the past decade, drone technology has made significant advancements, including the adaptation of  The two previous examples demonstrate the importance of proper cooling fan operation within machinery. Designing any system that requires

The two previous examples demonstrate the importance of proper cooling fan operation within machinery. Designing any system that requires