Intelligent Motion Control (IMC) solutions modify the start-up and continuous power in brushless DC fans and blowers. These systems control every element of the equipment's functionality with multi-featured, full-wave, in-board circuit designs to ensure each piece of equipment is protected from abnormal or harmful voltage conditions. Not only can the IMC solution control how much power is run through the fan and blower systems on start-up, but they can also provide early warnings about fan malfunctions and energy usage.

IMC solutions are commonly utilized in green facilities that want to maintain a high degree of energy-efficiency, as well as plants with significant amounts of electronic or heated equipment that needs regular cooling. The benefits of Intelligent Motion Controls include:

- Better operating efficiency and performance

- Improved system oversight and maintenance

- Electronic and fan or blower components that last longer

- Fewer voltage fluctuations

- Programmable features to build a customized solution for every facility or application

- Multi-alarm connections that run multiple fans and detect potential malfunctions quickly

Each of these individual benefits work together to make fan and blower systems perform better, longer, and more safely. It's essential to select an appropriate IMC solution that will optimize each of these benefits for the highest return on investment.

Solutions

Pelonis Technologies provides many IMC control solutions for brushless DC fans and blowers. Four of the most popular control types include:

- Pulse Width Modulation (PPWM)

- Over-Voltage (OV)

- Automatic Temperature Control (TPWM)

- Manual Variable Resistor Control (RPWM)

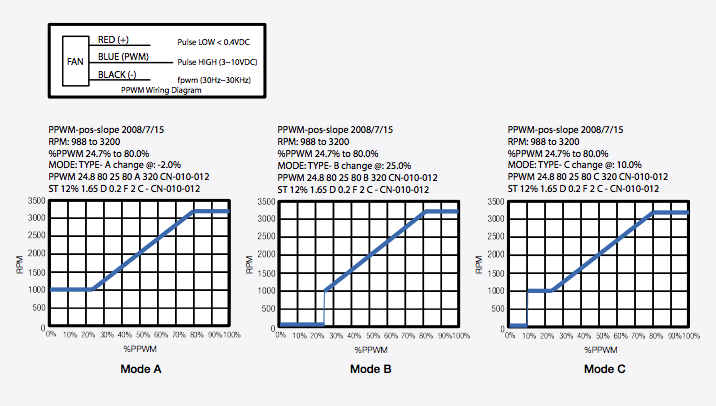

Pulse Width Modulation

PPWM controls allow facilities to directly manipulate signals within fan and blower systems to control how much time they spend operating on high settings. Complex circuitry systems frequently use PPWM systems to vary how much time equipment operates with a high signal. The system is analog and switches the equipment between high or low settings across a consistent period of time.

The control system works by applying a modulated signal with different frequencies ranging from 30 Hz up to 30 kHz. The high setting's pulse height can range from 3V–10V, and the low setting's maximum pulse height is 0.4V. These differences in voltage and signal change the fan system's duty cycle speed proportionally to the same percentage change in the maximum speed.

PPWM controls also include:

- Constant Speed (CS) controls

- Inrush Current Protection (IR) controls

- Current Limit (CL) controls

PPWM controls ensure that the fan maintains a minimum speed when the duty cycle is less than 25%, and cap the maximum speed at 4,000 RPM. This setting is called Mode "A" operation. These systems use an external blue wire.

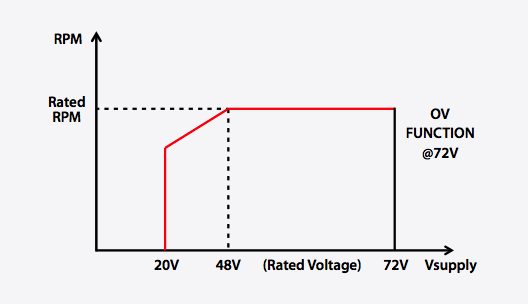

Over-Voltage

Inconsistent voltage levels can damage equipment, especially if the voltage surges above a maximum allowable level. Over-voltage systems are protective circuits that detect voltage levels and only allow the equipment to operate when the voltage is below an established safety threshold. This maximum operating voltage is typically set at 20% more than the specific rated voltage, but the level can be customized for different equipment.

Over-voltage systems either shut down power or clamp the output once it gets too high. The control's voltage range is double the rated voltage of the equipment it's protecting.

OV controls are built-in tools that don't have an external wire.

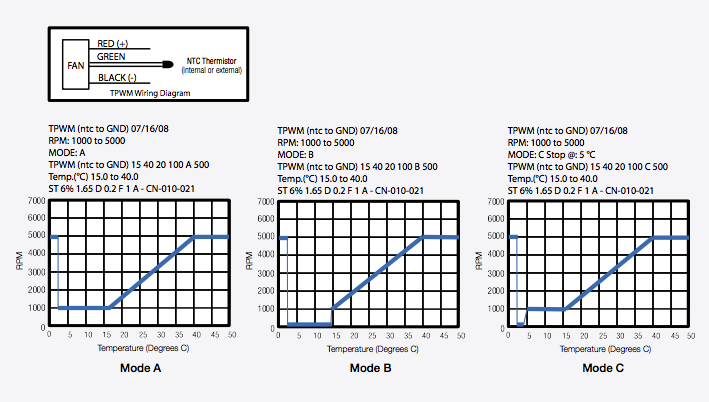

Automatic Temperature Control

Instead of keeping a facility's fans and blowers on a timer, TPWM systems read the temperature to determine whether the cooling equipment needs to be running at a low or high speed. Operators can customize the upper and lower temperature limits to dictate when the system's settings should change to lower the temperature or hold the temperature steady.

These systems use a 104J NTC thermistor, which offers 100K at 25° C. Also, the following controls come included in the system:

- Constant Speed (CS) controls

- Inrush Current Protection (IR) controls

- Current Limit (CL) controls

This system has a built-in safety in the event of open or shorted thermistors. In these conditions, the control will tell the fan or fans to run at maximum speeds. Also, the fan's Mode "A" operation will rotate at a minimum of 1,000 RPM in temperature conditions of 16° C (60.8° F) to maintain adequate airflow. These systems use an external green wire.

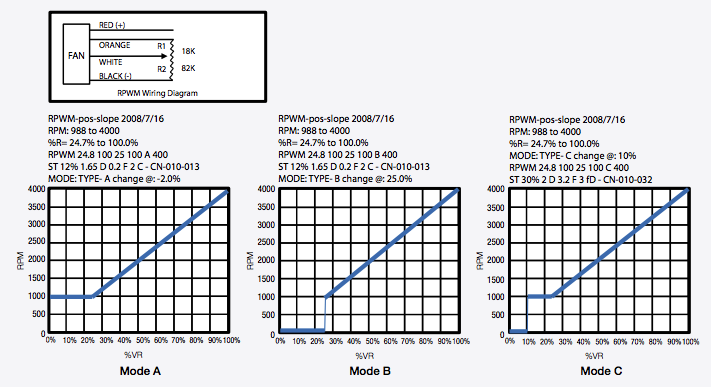

Manual Variable Resistor Control (RPWM)

Many applications—including controls for generators, DC motor drives, and electric welding controls—need to have manual control. Manual Variable Resistor Control systems allow operators to adjust the fan or blower speed at varying levels with an external variable resistor. The system's speed will change proportionally to the percentage change of the resistor and in correspondence to the percentage change of the maximum speed.

The systems come with a resistor with a maximum value allowance ranging from 10–100K. The maximum fan speed is 4,000 RPM. The following controls come included in the system:

- Constant Speed (CS) controls

- Inrush Current Protection (IR) controls

- Current Limit (CL) controls

If the variable resistor drops below 25K, then the RPWM automatically enters Mode "B" operation, and the fan will stop. These systems use external orange and white wires.

IMC Solutions from Pelonis Technologies

Choosing the right IMC solution to protect your facility's fan and blower systems is essential. Pelonis Technologies can help you select the best fit. Not only do we have a wide range of Intelligent Motion Controls, our products include rotation detectors, life detection systems, DC voltage system controls, and current source signal control systems.

Contact us today to learn more about upgrading your system.