Brushless DC fans and blowers need optimal motion control. When complex or demanding applications need precise levels of output, intelligent motion control systems can keep parts safe while still ensuring high-quality production cycles. These intelligent motion controls (IMCs) have in-board circuits that use programmable, information-gathering features to develop air movement “intelligence” and learn how the parts need to operate in different environments.

IMCs are ideal for:

- Green applications in which facility managers want to improve reliability, the equipment’s life expectancy, and energy efficiency.

- Systems that need consistent monitoring and cooling—IMCs have multi-alarm connections to prevent complete system failures, reduce voltage fluctuations, and have more reliable control.

When businesses install IMCs, they will make their facilities greener and more efficient. Read on to learn about all the different benefits IMCs can bring.

Top Solutions

There are several different types of IMCs that can add control to the operation and maintenance of brushless DC fans and blowers. The top four IMC solutions are:

Rotation Detectors

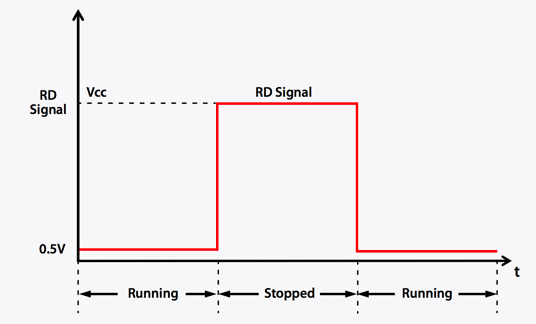

A smart rotation detector can monitor fan operations in parallel circuits to detect ongoing circulation as well as potential failures or stopped fans. These systems give a “high” output signal to the monitoring interface while the fan rotates. That same signal turns to “low” or “off” based on the fan’s status. This allows operators and maintenance teams to investigate potential problem areas more quickly because the system automatically notifies them when a fan stops working rather than requiring them to monitor changes in temperature.

Rotation detectors use the same hardware as the frequency generator (tachometer), which we also describe below. Once the detector is added to an array of fans, it operates as part of the facility’s multi-alarm connection.

Inrush Current Protection

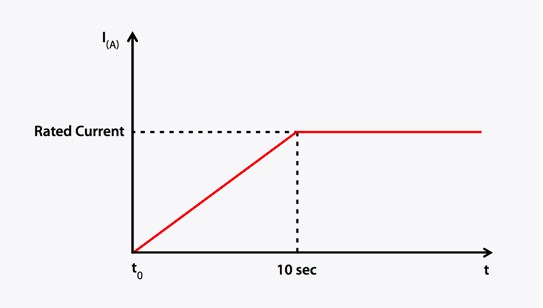

When motors, heating elements, transformers, and power supplies turn on, the current surges. This short-lived inrush current can damage electronic parts if it isn’t properly controlled.

Facility managers use inrush current protection to slow the flood of current to the equipment. This technology allows fan blades to speed up at a more gradual rate through incremental increases of current. The process takes approximately ten seconds during startup, and it protects both the circuits and the moving parts from damage.

Auto Start

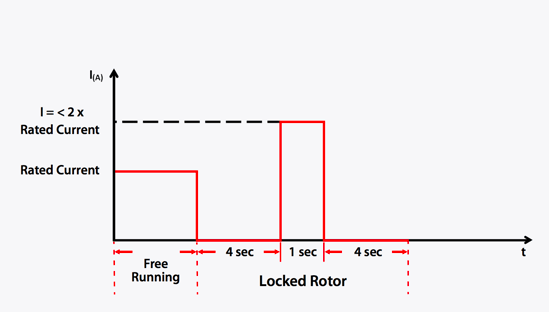

Sometimes, fan blades get blocked by temporary obstructions. Auto starts control the current output in these circumstances. First, the current can be reduced to zero when an obstruction is detected so the fan blades don’t damage themselves. This feature is called locked rotor protection. Then, the auto-start control uses a second feature, restart with current limit, to guarantee the restart of the rotor once it is released.

Frequency Generator (Tachometer)

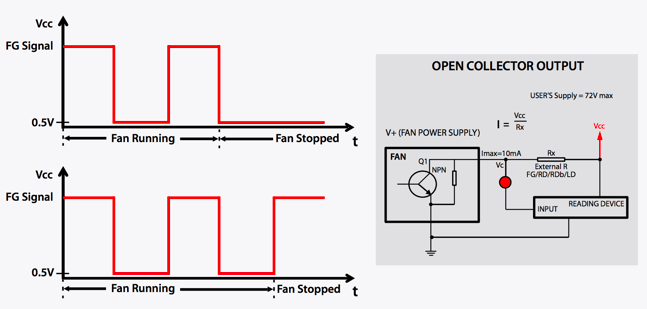

This IMC solution is an open collective output type that produces an analog voltage based on the fan’s motor speed. These parts provide feedback and can be used to measure the speed of motors, rotors, and engines.

Frequency generators use the same hardware as rotation detectors, and they’re powered by the power supply voltage. A tachometer will send a square wave signal to the reading device if the collector connects with a pullup resistor. This part can handle a maximum collector voltage of 72 V DC and current of 10 mA.

Quality IMC Solutions from Pelonis Technologies, Inc.

Smart IMC solutions keep your equipment’s DC blowers and fans operating at their full potential. These tools also extend the lifespan of your equipment and protect electronics from the dangers of overheating.

Pelonis Technologies, Inc., provides a wide array of fans, blowers, and other cooling and heating solutions. Contact our team to learn about our customization services or to browse our design catalog.