Finding efficient ways to heat the world is becoming more important by the day. With energy resources becoming more expensive and harder to find, the world is constantly on the hunt for new ways to save both money and the earth itself. One such innovation is PTC Heating.

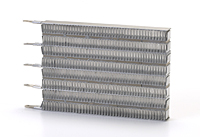

PTC, which stands for Positive Temperature Coefficient, is a method of heating that relies on ceramic stones rather than traditional resistance wire. Ceramic stones are unique semiconductors that not only heat quicker but also reach a point where the heat they generate is sufficient to make up for the heat being lost into the air.

This allows PTC heaters to react to the ambient temperature around them, which in turn makes the heater shut off if it exceeds a preset temperature.

In more simple terms, the heaters never get hotter than they need to be, so you save energy. This combined with quicker heating makes for a super efficient heat source.

There is a good chance you have experienced PTC heaters without actually realizing it. Things like curling irons, coffee makers, and those little air fresheners that you plug into the wall, all use PTC technology.

Now, what’s especially beneficial is how these heaters are self-regulating. The PTC heater will adjust its consumption accordingly as conditions in the environment change. In other words, when the optimal temperature is achieved, a PTC heating element will “back off” and maintain the lowest possible output to preserve its intended temperature.

For instance, if the heated environment is a closed room and someone opens the door, then the system will adjust to the loss of heat until the intended temperature is again achieved. Since it is self-regulating and designed for “fail to cold,” it is virtually impossible for them to overheat. This is a considerable safety feature to keep in mind.

Aside from the overall increase in safety, which should always be paramount, PTC heaters also offer a number of other benefits. The reduced cost of upkeep will be significant, as there are fewer functioning components to fail or suffer from wear and tear.

The ceramic components are highly resistant to a number of industrial hazards, like corrosives. Since the heating system is self-regulating you will see a drop in energy consumption, and because the system doesn’t continue heating beyond what’s needed, it also eliminates the need for consistent monitoring.

Since the internal components aren’t constantly running at high temperatures (and there are fewer components to begin with), the durability factor skyrockets with PTC heaters. High, consistent heat tends to wear materials down. Without that issue, usage of PTC heaters results in less downtime and cost for to repair.

At Pelonis, we offer industrial clients a wide selection of high quality PTC technology.

At Pelonis, we offer industrial clients a wide selection of high quality PTC technology.

If you want to green your heating system, then you really should check out Pelonis’ PTC heaters. Nothing beats saving money and the earth at the same time!