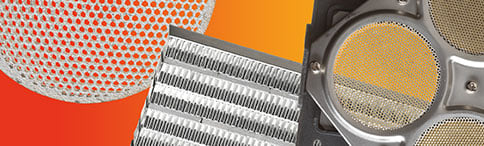

Quality Manufacturing

Our Focus is Quality

For Pelonis Technologies, manufacturing quality means adhering to and surpassing industry standards. Our highly trained engineering and quality control teams, special test equipment, and stringent testing procedures all ensure continuous quality production at all times.

Quality Standards

- ISO 9000 and ISO 14000 quality certification

- Industry standards including testing and compliance in accordance with UL, CUL, TUV, and CE requirements

- Highly trained technical and Quality Control Inspection staff with thorough knowledge of industry standards and customer requirements

Quality Test Equipment

- Dual chamber airflow equipment measures product airflow performance, static pressure, speed, and power

- Anechoic Chamber with low background noise tests fan noise performance

- Micrometer test equipment ensures exact component dimensions

- Special coating methods using automatic conveyor systems reduce motor winding noise and enhance product longevity

- High temperature ovens running at 50 degrees Celsius enhance product performance and reduce failure rate in high ambient temperature conditions

- Automatic winding equipment using high grade silicone steel

Quality Control Procedures

- High temperature testing methods utilizing ovens with temperatures ranging from -40 degrees Celsius to +100 degrees Celsius

- Continuous endurance testing ensures that components meet required specifications

- Burn-in testing procedures using Burning Room with temperature testing above 70 degrees Celsius ensure product quality under worst case operating conditions

- Use of high quality bearings with proven ANSI, ASA, and MIL-STD quality standards

- L-10 life testing procedures monitor product life

Resources

Resources Contact

Contact (US) 888-546-0524

(US) 888-546-0524